Interactive Quick Picker

Above-the-fold calculator • Exports • Share URLEnter your tank dimensions, head height and species. We’ll compute working water volume, target real-world flow, loss multipliers, and the rated GPH you should shop for.

Results

auto-updates- Working water volume: —

- Target real flow: —

- Estimated losses (head+hose / media): —

- Bio-load multiplier: —

- Rated GPH needed (with safety): —

- Recommended setup: —

- Maintenance cadence: —

Notes & Tips

- Use a prefilter sponge on the intake for easy weekly rinses.

- Wider hoses and shorter runs preserve real flow.

- Never rinse biological media in chlorinated tap water.

- Two medium canisters in parallel beat one choking giant.

Flow & Sizing Math, Explained

Box ratings claim ideal lab conditions. Turtles add heavy bio-load, fine debris, and head height that erode real-world flow. We’ll compute the rated flow you should shop for so that you still achieve your target real flow at home.

1) Working Water Volume

We start with internal dimensions. Apply the fill level, subtract displacement from basking platforms and substrate. For substrate we assume ~50% porosity: only half the volume displaces water.

Vwork = L × W × (H × fill) − Vgear − (L × W × depthsubstrate × (1 − porosity))

2) Target Real Flow

Choose turnover per hour (turtles like 6–12×/hr; we default to 8×). Multiply by volume to get real-world flow target.

Qtarget = Vwork × turnover

3) Multipliers: Bio-load, Media/Clogging, Head/Hose

- Bio-load (

Fb): sliders/painted are dirtier than musk/mud. Adults generate more waste than hatchlings. - Media/clog (

Fm): denser pads and longer cleaning intervals increase resistance. - Head + hose (

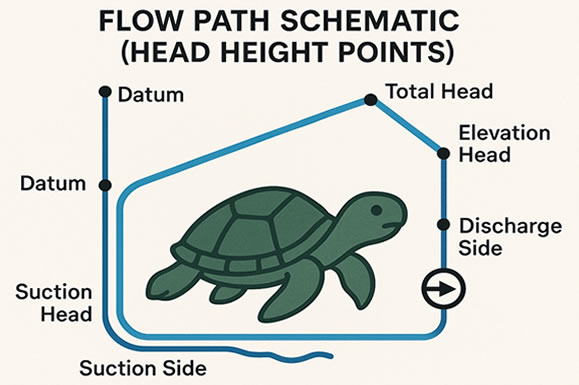

Fh): elevation and tubing friction eat flow; narrow hoses penalize more.

Qrated ≈ Qtarget × Fb × Fm × Fh × safety (safety ~1.25)

Worked Examples

- 75-gal Slider @ 4 ft head: High bio-load and head loss → rated GPH can reach ~900–1200 depending on media and hose. Parallel mid-size canisters recommended.

- 40-breeder Musk @ 2.5 ft head: Lower bio-load; with wide hoses and prefilter, a 300–450 rated GPH unit commonly meets the real-flow target with margin.

Head Height & Hose Loss Estimator

Tip: Widening from 1/2" to 5/8" can reclaim 5–10% real flow; trimming 2 ft of hose can yield noticeable gains.

Media Strategy & Prefiltering

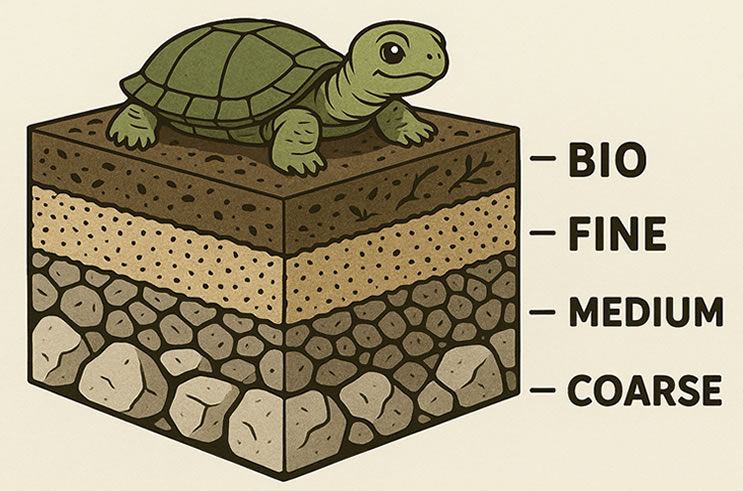

Stage your media so that coarse debris is trapped first, preserving fine pads and keeping bio media oxygenated. Add an intake prefilter you can squeeze-rinse weekly—this keeps your canister flowing longer between services.

| Media layer | Purpose | Derate if not serviced | Service interval |

|---|---|---|---|

| Coarse sponge | Catch large debris | +3–5% flow loss | Rinse weekly |

| Medium pad | Fines + polish | +5–8% | 2–3 weeks |

| Fine pad | Water clarity | +8–12% | Weekly if used |

| Bio media | Ammonia→Nitrite→Nitrate | Negligible if not clogged | Rinse in tank water only |

Configuration Scenarios

Hatchling in 30-gal tote

- Lower head height; frequent prefilter rinses.

- Target 6–8× turnover; avoid blasting the turtle.

- Choose wide hoses even on compact filters.

75–90 gal adult Slider

- Dual prefilters; more media volume.

- Consider two mid-size canisters in parallel for redundancy.

- Set maintenance every 3–4 weeks.

125–150 gal stock tank

- Compare one XL canister vs sump; sumps excel at oxygenation.

- Plumb returns near the surface for agitation.

Musk/Mud compact setup

- Lower bio-load; 6–8× often sufficient.

- Prefilter discipline keeps clarity high.

Brand-Agnostic Canister Comparison (Template)

Fill with any models you’re considering. “Real @ 4 ft” is estimated at ~65% of box rating by default—edit as you measure.

| Model | Rated flow (gph) | Real @ 4 ft (est.) | Max head (ft) | Media volume (L) | Hose ID | Power (W) | Noise (dB) | Footprint | Price band | Turtle-ready score |

|---|---|---|---|---|---|---|---|---|---|---|

| Generic Canister 1000 | 300 | 195 | 6.0 | 3.0 | 5/8 | 18 | 45 | 11×9 in | $ | 7.4 |

| Generic Canister 1500 | 450 | 290 | 7.0 | 5.0 | 5/8 | 28 | 47 | 12×10 in | $$ | 8.1 |

| Generic Canister 2000 | 650 | 420 | 8.0 | 7.0 | 3/4 | 35 | 49 | 13×12 in | $$$ | 8.7 |

How-To Blocks

Prime and De-air a Canister (Checklist)

- Fill the canister with tank water to cover the impeller housing.

- Attach hoses without kinks; ensure the intake is submerged.

- Open valves and use primer pump if present to flood hoses.

- Power on; tilt gently to purge trapped air.

- Top off tank; check for microbubbles after 10–15 minutes.

Measure Real Filter Flow (Bucket Method)

- Detach the return into a measured bucket.

- Time how long it takes to fill to a marked volume.

- Compute gph = (gallons / seconds) × 3600.

- Compare to target; adjust media pads or hose routing if needed.

Troubleshooting Matrix

| Symptom | Likely cause | Fix |

|---|---|---|

| Microbubbles | Trapped air or cavitation | Tilt canister, check intake depth and seals |

| Noisy impeller | Debris on rotor | Clean rotor chamber; replace worn bushings |

| Cloudy water | Insufficient mechanical stage | Add/coarsen prefilter; service pads more often |

| Falling flow | Clogged pad or narrow hose | Rinse pads; upgrade to 5/8–3/4" hose |

| Persistent odor | Anaerobic media | Reduce fine pads; improve oxygenation; service cadence |

FAQ

Safety: Use GFCI outlets and a drip loop. Dry hands before service. Monitor ammonia and nitrite especially with juveniles.